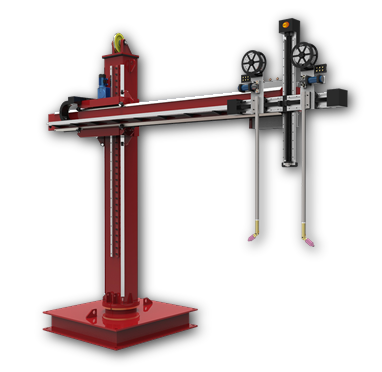

PEC's Single and Twin Arc Conventional Weld Cladding Systems

Key benefits

• Can weld components up to 3000 mm height

• Can weld bores up to 2300 mm diameter

• Proven equipment technology

• Easily scalable to meet your different job sizes and requirements

• Uses standard mechanical hardware available from various suppliers

• Low capital costs

• Vertical or horizontal slide assemblly

• Wide range of columns and booms and turntables to suit the application

• Multiple turntable systems for higher productivity

• Pipe rotating systems

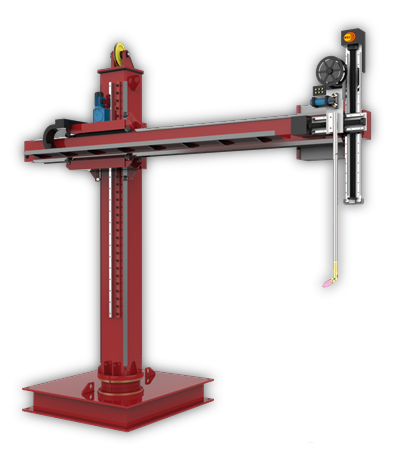

Conventional weld cladding is carried out primarily in circular bores with simple surfaces.

The component is mounted on a turntable with the bore being welded centred on the turntable rotational axis. During the cladding operation, the turntable rotates and the welding torch is stationary (moving up once a revolution). A conventional column & boom (rack & pinion type) supports precision cross slides attached to the end of the boom. The slides perform the task of moving the torch in two or more axes.

Using this configuration of hardware, components of up to 20 ton in weights and 3 metres in heights can be welded. For heavier components, we recommend our Rotary Head system.

PEC conventional systems utilise PEC's proven MultiCLAD system controller which has been continuously developed on extensive research based on feedback from our customers.

The component is mounted on a turntable with the bore being welded centred on the turntable rotational axis. During the cladding operation, the turntable rotates and the welding torch is stationary (moving up once a revolution). A conventional column & boom (rack & pinion type) supports precision cross slides attached to the end of the boom. The slides perform the task of moving the torch in two or more axes.

Using this configuration of hardware, components of up to 20 ton in weights and 3 metres in heights can be welded. For heavier components, we recommend our Rotary Head system.

PEC conventional systems utilise PEC's proven MultiCLAD system controller which has been continuously developed on extensive research based on feedback from our customers.

CCS - 1

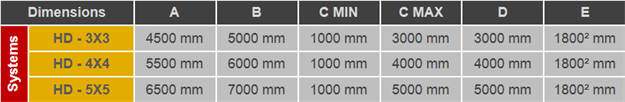

Horizontal/Vertical NC Cladding Systems

Where more complex surfaces (e.g. cross bores, seat pockets) need to be welded, we offer the Precision NC cladding system which is still of the conventional format i.e. has a turntable, but dispenses with the cross slides. The column & boom (which uses high accuracy ball screws and rails) performs all precision torch movements. Also, the column is mechanically very compact as the boom does not intrude into the space behind the column as is the case in a conventional column and boom. This arrangement is ideal where ground space is at a premium.

Key Benefits of the Precision Cladding System

• Precision movements (2000 mm) of the torch in the horizontal and vertical

axes resulting in excellent weld finish

• Ideal for welding pipes, tubing hangers and spool bodies

• Welds valves with cross bores, racetracks bores etc.

• Compact mechanical arrangement saves floor space

• Most advanced type of conventional cladding system available

CCS - 2

Scope of use

• Continuous weld cladding of components

• Reduced machining time due to uniform and precision application

of weld overlay material

• Low weld defect rates (less than 1%)

• Weld cladding on a range of base materials and with a variety of

weld overlay wires

• Ability to weld surfaces with limited access, small dimensions

• Fully computerised parameter programming

• Weld parameter screen edits permitted during a weld cycle

• Single pass welding with iron dilution under 5% and weld thickness

up to 7 mm

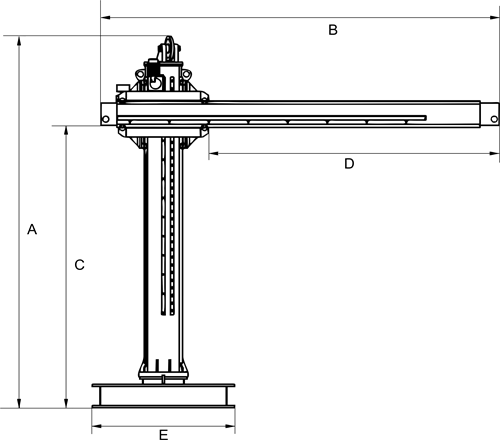

System Dimensions:

A - Column height

B - Boom length

C - Boom travel distance (Y axis)

D - Boom travel distance (X axis)

E - Base dimensions

A - Column height

B - Boom length

C - Boom travel distance (Y axis)

D - Boom travel distance (X axis)

E - Base dimensions

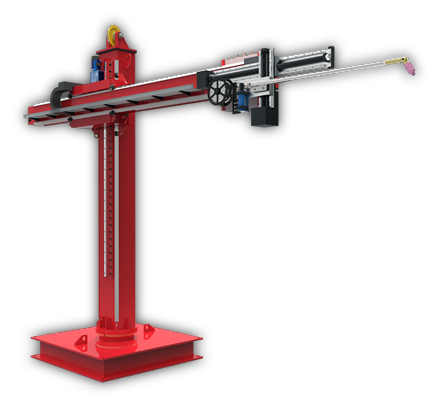

CS1001 - 1000 mm vertical travel - single torch

CS1002 - 1000 mm vertical travel - twin torch

CS1501 - 1500 mm vertical travel - single torch

CS1502 - 1500 mm vertical travel - twin torch

CS1002 - 1000 mm vertical travel - twin torch

CS1501 - 1500 mm vertical travel - single torch

CS1502 - 1500 mm vertical travel - twin torch

Turntables : 3-20 ton capacities

Tilt/Turn Positioners : 3-20 ton capacities

Pipe Rotating Systems : 2-6 ton capacities - higher capacities available on request

Tilt/Turn Positioners : 3-20 ton capacities

Pipe Rotating Systems : 2-6 ton capacities - higher capacities available on request

CS-1001

Horizontal Position

Horizontal Position

COMPANY

SYSTEMS

INFORMATION

CONNECTION

Phone:

Fax:

Fax:

Copyright © Power Electronics & Controls Ltd - 2015

+44 (0)1536 310070

+44 (0)1536 525466

+44 (0)1536 525466