Key Features

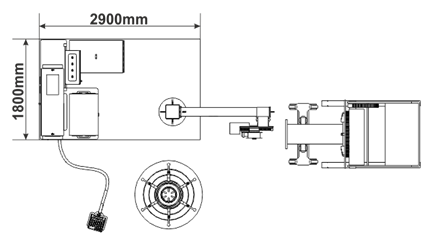

• Compact layout

• Rotating torch slides

• Vertical and horizontal welding

• Easy set up and control of welding parameters

• User friendly touch panel interface

• Monitor of all essential welding variables

• Wide range of applications

• Multiple turntable and positioner configurations

• High precision torch slides for superior weld quality

• Purchase or rental options

Applications

• Valves bodies

• Pipes

• Ring grooves and seal areas

• Cross bores and seat pockets

• Tapered bores

Overview

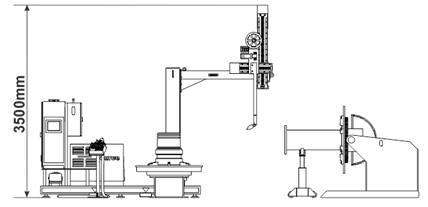

• The AC-1010 is a compact and highly versatile TIG Cladding system for all manners of overlay applications.

• The small footprint allows the AC-1010 to maximise shop floor space whilst providing a wide range of advanced

automatic functions for high-quality weld cladding of oil, gas and nuclear industry components.

• Multiple turntables and positioners can be integrated to the system to expand the productivity and capability of the

system.

• Job set up is fast and efficient with the easy-to-use interface and heavy-duty pendant remote control.

• Real-time welding variable feedbacks are displayed to allow quality control of the process.

• Affordable finance options including extended payment terms or rental contract.

*Turntable, positioner and adjustable pipe supporter are optional

COMPANY

SYSTEMS

INFORMATION

CONNECTION

Phone:

Fax:

Fax:

Copyright © Power Electronics & Controls Ltd - 2015

+44 (0)1536 310070

+44 (0)1536 525466

+44 (0)1536 525466