Robust Hotwire TIG Welding Torches

If you cannot reach it or enter it, you cannot weld it!

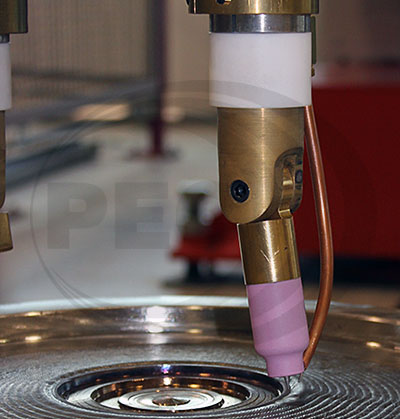

Nearly all weld cladding of well head valves is inside flow and cavity bores. The diameter of these bores vary from 38 mm upwards and lengths up to 3000 mm. Meeting these varied specifications requires welding torches with different physical geometries. The welding torch has to also work in an environment of high temperatures (more than 400°C) conducting high welding currents (up to 300 Amperes) and intense ultra violet radiation from the welding arc.

PEC's range of torches are fully compensated by design for above adversed criteria and are compatible with our Conventional and Rotary Head Hotwire TIG weld cladding systems

PEC's range of torches are fully compensated by design for above adversed criteria and are compatible with our Conventional and Rotary Head Hotwire TIG weld cladding systems

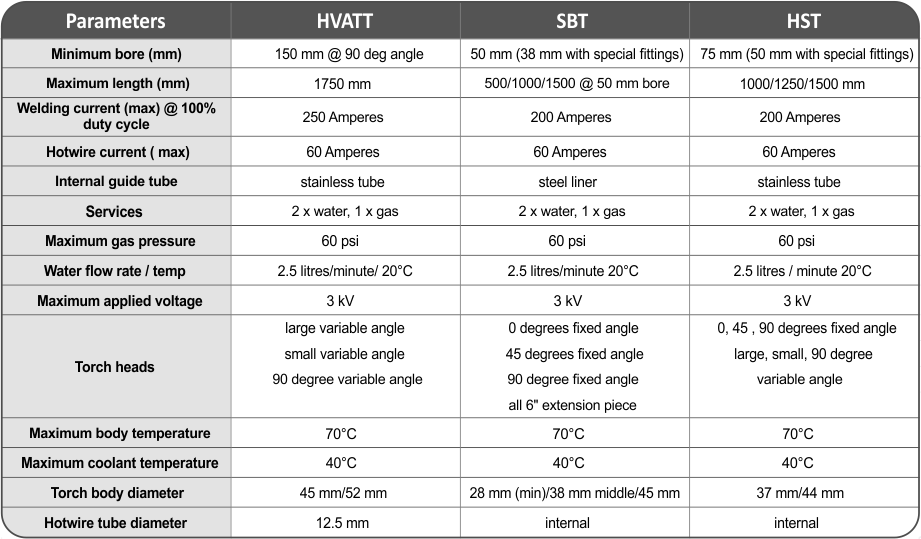

HVATT Torch - weld cladding of bores up to 2000 mm

The mechanical stiffness of PEC's HVATT TIG torches is achieved by design - i.e. mathematics relating mechanical stiffness and mechanical resonance. By careful choice of the torch construction materials and tube geometry, it is possible to minimize the torch "bounce" to acceptable levels. Complete arc stability (no "bounce") is only achievable by additional electronic means using the torch stability control system that is part of the PEC MultiCLAD controller.

The control system detects and quickly corrects the resonance effect, restoring normal arc stability. This feature is unique to PEC weld cladding systems and should be an important consideration when selecting between competitive supplier products.

The HVATT torch is also used for horizontal (1G) weld cladding using PEC's TwinWire Hotwire TIG process with torch oscillation. Torch 'bounce' is well controlled due to the HVATT torch mechanical stiffness and the electronic torch stability control.

The control system detects and quickly corrects the resonance effect, restoring normal arc stability. This feature is unique to PEC weld cladding systems and should be an important consideration when selecting between competitive supplier products.

The HVATT torch is also used for horizontal (1G) weld cladding using PEC's TwinWire Hotwire TIG process with torch oscillation. Torch 'bounce' is well controlled due to the HVATT torch mechanical stiffness and the electronic torch stability control.

SBT Torch - weld cladding of small bores (1.5"/38 mm)

HST Torch - TwinArc TIG weld cladding

Welding small bore (38 mm) is very difficult due to limited access for the torch head and body. This is particularly true in TIG welding where at least two layers off weld are required to meet dilution and weld thickness requirements. Common welding problems include asymmetrical (oval shape) welds, excessive iron dilution, weld cracking and poor weld finish.

PEC have many years of experience in small bore welding and our designers have a variety of proven solutions that can be engineered to suit your application. Our SBT torches are supplied with a range of angled heads and small bore adaptors to weld bores down to 38 mm diameters.

It should be noted that welding technique plays a very important role in welding inside small bore. Recent improvements in our Torch Stability control system has resulted in SBT Torches being available in lengths of up to 1500 mm. This permits TwinArc TIG welding of 4" diameter flow bores in Xmas tree valve block- a considerable saving in welding time.

PEC have many years of experience in small bore welding and our designers have a variety of proven solutions that can be engineered to suit your application. Our SBT torches are supplied with a range of angled heads and small bore adaptors to weld bores down to 38 mm diameters.

It should be noted that welding technique plays a very important role in welding inside small bore. Recent improvements in our Torch Stability control system has resulted in SBT Torches being available in lengths of up to 1500 mm. This permits TwinArc TIG welding of 4" diameter flow bores in Xmas tree valve block- a considerable saving in welding time.

PEC's unique TwinArc Hotwire TIG process reduces welding times by 50%. The presence of two torches within the bore presents a physical limitation for the minimum bore size that can be welded. This required the development of the HST torch where all services including the wire guide and hotwire tubes are placed internal to the body of the torch. TwinArc TIG welding using the HST torch is regularly carried out in bores as small as 5" and lengths up to 1500 mm.

The HST torch can be used in SingleArc applications in bores as small as 50 mm (2") at the full welding current (200 Amperes) and in hotwire mode. As the water cooling is taken right down to the torch heads, the gas diffuser, tungsten electrode and collet all work within their specified ratings. In other makes of torches, air cooled extensions are used to achieve the same result but with considerable overheating problems.

The HST torch can be used in SingleArc applications in bores as small as 50 mm (2") at the full welding current (200 Amperes) and in hotwire mode. As the water cooling is taken right down to the torch heads, the gas diffuser, tungsten electrode and collet all work within their specified ratings. In other makes of torches, air cooled extensions are used to achieve the same result but with considerable overheating problems.

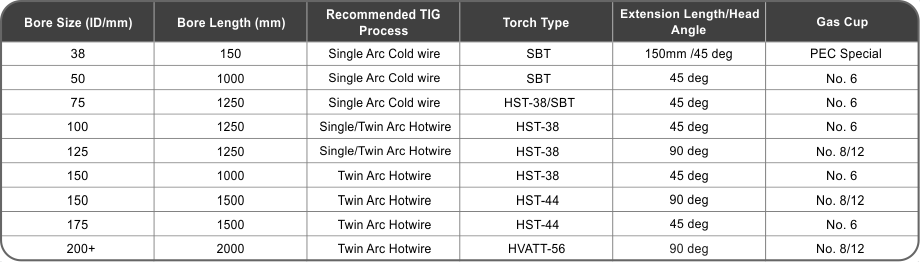

Selection of torch type, configuration and welding process

It is highly recommended that you check that the potential supplier of your cladding system has the torches that will be able to successfully weld the bores at the minimum diameter and maximum length in your product range. The cost of a welding torch is about 1% of the total system investment yet determines 100% of the ability to weld the required bore.

Some cladding tasks require custom extensions for challenging angles and bore access for the torch. PEC can assist you with these requirements. Please contact us today.

The Table below provides recommendation on the types of PEC torches and welding processes to weld bores of different diameters and lengths.

Some cladding tasks require custom extensions for challenging angles and bore access for the torch. PEC can assist you with these requirements. Please contact us today.

The Table below provides recommendation on the types of PEC torches and welding processes to weld bores of different diameters and lengths.

COMPANY

SYSTEMS

INFORMATION

CONNECTION

Phone:

Fax:

Fax:

Copyright © Power Electronics & Controls Ltd - 2015

+44 (0)1536 310070

+44 (0)1536 525466

+44 (0)1536 525466